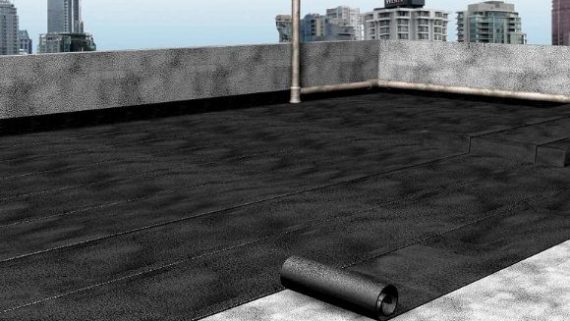

Modified Bitumen Based Waterproofing Membrane For Roofs & Basements

Uses area of Bituminous Membrane Waterproofing:

-

Bituminous membrane waterproofing finds diverse applications across multiple sectors due to its effectiveness and versatility. Some specific uses include:

1. Roofing Systems

2. Below-grade waterproofing (basements, foundations, and retaining walls)

3. Bridge Decks and Infrastructure

4. Tunnel Linings

5. Plaza Decks and Podiums

6. Green Roof Systems

7. Submerged Applications (swimming pools, reservoirs, and water treatment facilities)

8. Landscaping and Planter Boxes

Advantages of Bituminous Membrane Waterproofing:

-

1. Superior material durability compared to other systems.

2. Exceptional flexibility, accommodating structural movements effectively.

3. Versatile application methods, ensuring efficient and cost-effective installations.

4. Seamless protection with minimal risk of water infiltration.

5. Environmentally friendly properties, utilizing recycled materials and offering recyclability.

6. Resistance to root penetration, ideal for green roof applications.

7. Cost-effectiveness over the long term, with lower maintenance expenses.

Application procedure:

Step 1: Surface Preparation

Step 2: Priming (if necessary)

Step 3: Cutting and Shaping Membrane

Step 4: Application of Adhesive

Step 5: Membrane Installation

Step 6: Seam Sealing

Step 7: Detail Work

Step 8: Protection Layer (Optional)

Step 9: Final Inspection