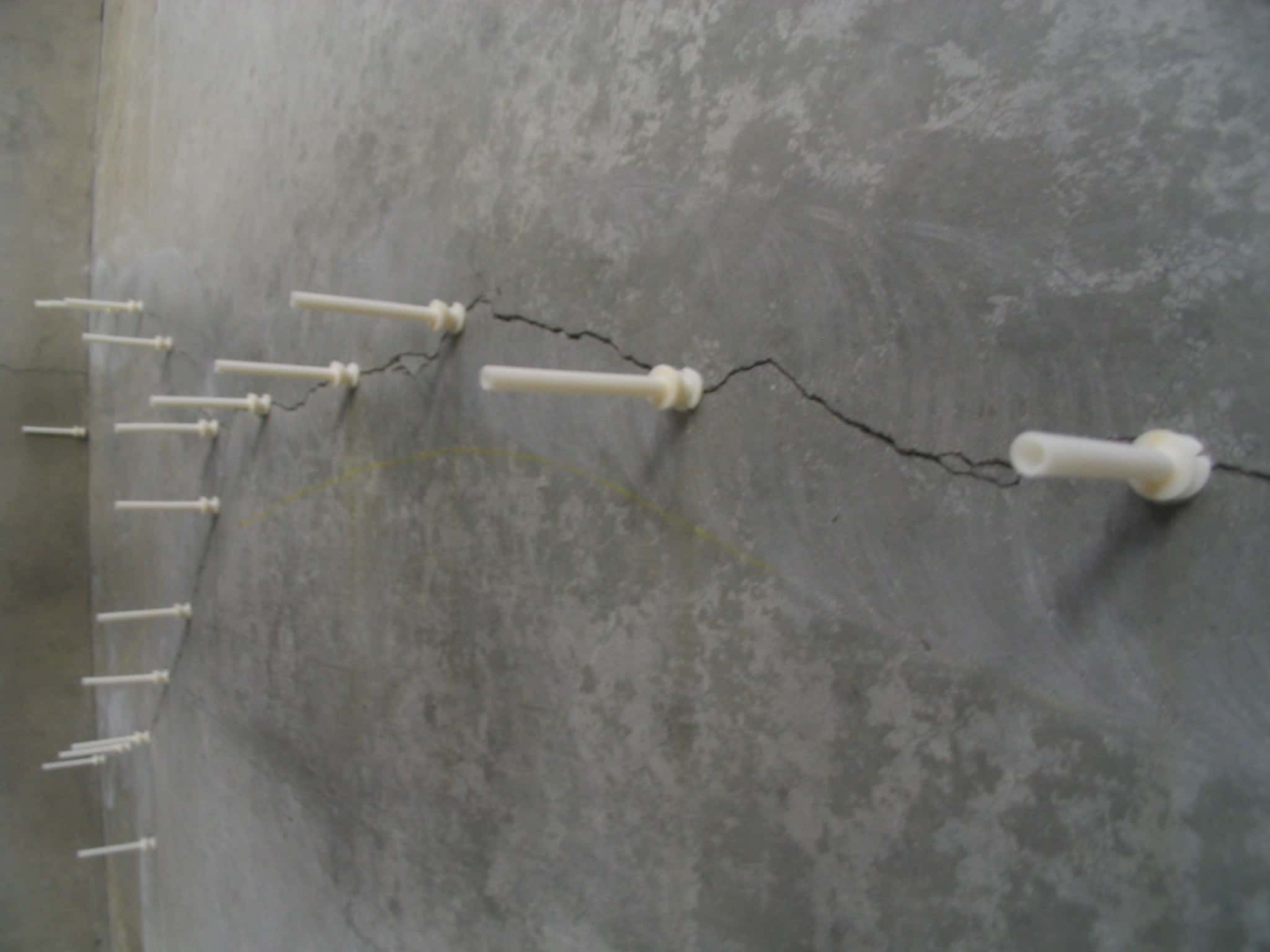

Crack repair injection is specialized to use to repair cracks in concrete structures, ensuring they regain their original strength and durability. This method involves injecting low-viscosity materials such as epoxy or polyurethane into the cracks to fill them and prevent further damage. The epoxy injection crack repair process is particularly effective for restoring the structural integrity of concrete.

Moreover the origins of crack repair injection date back to the mid-20th century when engineers sought innovative methods to address cracks in concrete structures. Early solutions, such as surface patching, were temporary and often failed under long-term stress. With advancements in materials science, epoxy injection crack repair became a permanent and reliable solution for treating cracks. By the 1970s, this method became the standard for repairing concrete in large infrastructure projects like bridges, dams, and buildings.

Types of Crack Repair Injection

- Epoxy Injection: Epoxy injection crack repair is one of the most reliable methods for structural crack repair. Hence it involves injecting a high-strength epoxy resin into the cracks to restore the original strength and bonding of the concrete. This method is ideal for repairing narrow cracks. Addition it is often used in situations where restoring the structural integrity is critical.

- Polyurethane Injection: Polyurethane injection is commonly used for concrete injection repair in areas prone to water infiltration. It involves injecting a flexible, expanding polyurethane foam into the cracks to create a watertight seal. This method is ideal for non-structural crack repairs, such as leaks in basements, tunnels, and water tanks.

- Cementitious Grout Injection: In some cases, cementitious grout can be used for concrete injection repair, especially for larger, non-moving cracks. This method of foundation repair and other large-scale concrete restoration projects.

Benefits and Usage Areas of Crack Repair Injection

- Restores Structural Integrity: Epoxy injection crack repair provides a strong, permanent bond that restores the structural capacity of the concrete, ensuring long-term durability.

- Prevents Water Infiltration: Concrete injection repair with polyurethane forms a watertight seal, protecting the structure from water damage and extending its lifespan.

- Cost-Effective Solution: Compared to replacing entire sections of damaged concrete, crack repair injection is a more affordable solution that saves time and resources.

- Non-Invasive Process: The injection process is relatively quick and non-invasive, allowing repairs to be done without disrupting the overall structure.

- Bridges and Dams: Concrete injection methods are commonly use in large-scale infrastructure projects.

- Basements and Foundations: Epoxy injection and polyurethane are often used to repair cracks in basements and foundations.

- Parking Structures: Heavy loads and environmental exposure can cause cracks in parking structures, making crack repair injection a prefer method for long-lasting repairs.

- Industrial Floors: Industrial floors often suffer from wear and tear, leading to cracks. Concrete injection repair is essential for restoring these surfaces and maintaining safety.

- Tunnels and Water Tanks: Cracks in tunnels and water tanks are typically repaired using polyurethane injections.

Crack repair injection is an essential method for maintaining and restoring the durability of concrete structures. Whether through epoxy injection crack repair for structural purposes or polyurethane for waterproofing. Besides his method offers a long-lasting, cost-effective solution. From bridges and industrial floors to basements and tunnels.

By understanding the different types of concrete injection repair and their benefits, Fountech can help you choose the best solution for your project. Our expertise in epoxy injection and other repair methods ensures top-quality results that meet your structural needs.