What is Electrostatic Discharge (ESD) flooring?

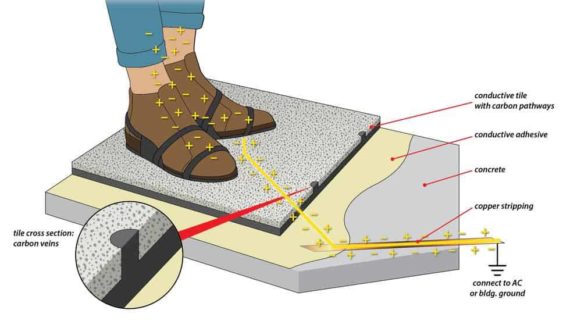

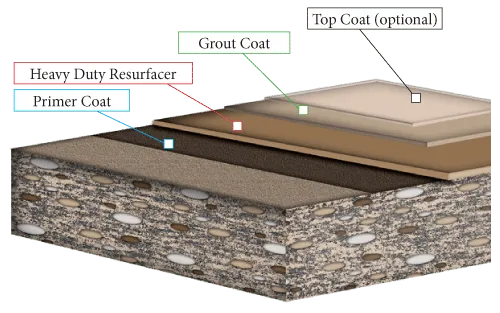

Conductive epoxy flooring systems provide the least amount of charge creation and the fastest charge dissipation for an ESD production environment. One copper grounding needs a strip for every 1000 sq. ft. In today’s technologically advanced world, electronic devices are an integral part of our daily lives. However, with the increasing reliance on sensitive electronic equipment comes the risk of damage caused by Electrostatic Discharge (ESD). To mitigate this risk, industries and facilities often turn to specialized flooring solutions designed to dissipate static electricity. Electronic resistance values for esd anti-static flooring are set between 2.5 × 104Ω and 1 × 109Ω. In this guide, we delve into the concept of Electrostatic Discharge (ESD) flooring and explore key elements such as Conductive epoxy, anti-static epoxy floor paint, conductive floor tiles and the electrostatic discharge test. The thermally conductive epoxy ensures not only static control but also efficient heat dissipation, making it an ideal choice for spaces with intricate electronic systems.

Why Electrostatic Discharge (ESD) flooring is required?

Electronics are shielded from harm by static electricity by Electrostatic Discharge (ESD) flooring, which builds up as people walk. Electrical conductivity is provided to ESD floors by conductive components incorporated into the flooring material, such as carbon, graphite, or metal-coated particles, which form an electrical channel connecting the walking surface to the ground. Electrostatic discharge (ESD) flooring is a critical necessity in environments where sensitive electronic equipment operates.

In today’s tech-driven landscape, electrostatic discharge flooring is imperative to ensure the longevity and functionality of sensitive electronic equipment. ESD flooring/ESD Static epoxy floor paint is an easy way to help static accumulation in the human body or outfit through an electrical connection between the human body or outfit.

To validate the effectiveness of an ESD flooring system, regular electrostatic discharge test are essential. These tests assess the ability of the flooring to safely and consistently dissipate static charges. Utilizing materials such as Conductive epoxy, anti-static epoxy floor paint, and conductive floor tiles along with regular electrostatic discharge test, ensures a robust and reliable solution for preventing damage caused by static electricity.

Our comprehensive range, featuring Conductive epoxy, anti-static epoxy floor paint, and thermally conductive epoxy, establishes a robust line of defense against electrostatic discharge. From conductive floor tiles to esd epoxy floor paint, our solutions are tailored for diverse environments. . Trust in our expertise to secure your critical operations and uphold the integrity of your electronic systems.

We also completed thousands of floor projects all over Bangladesh with industrial Epoxy /PU floor, Floor hardener, polish concrete, and Conductive epoxy flooring Besides, the last few years. we have been the representatives of contractors, distributors, and suppliers procuring renowned manufacturing companies like DPF Malaysia, Elite Crete BD, Ducon, Viacor, Pidilite, etc.

Available Color Chart

ESD Flooring Usages Areas

- Research and development space

- Clean electronics manufacturing facility Clean room

- Space assembly area

- Auto Manufacturing Assembly and Test Lab

- Solvent storage area

ESD Flooring Advantages

- Controls static discharge

- Time proven performance

- Long-term durability

- High impact resistance

- Maximum wear resistance

- Thermal shock resistance

- Chemical resistance

- Virtually seamless, Self-priming

- No joints to harbor bacteria

- Rapid cure/safe, fast installation

- Odorless, non-toxic, non-tainting

- Regulatory agency approved

- Variety of colors, designs and textures

- Durable

- Low maintenance

- Easy to clean